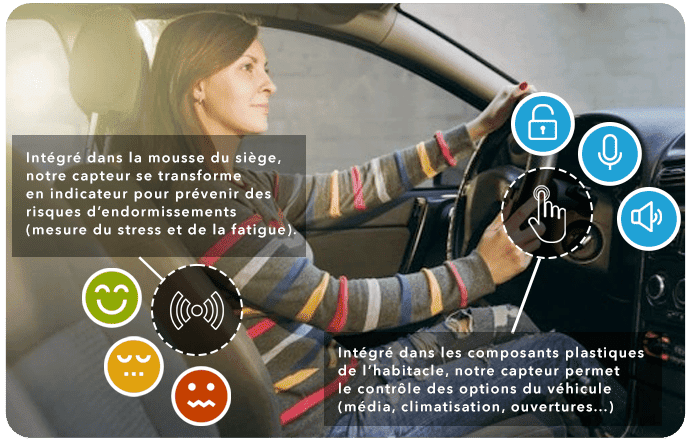

Nanomade turns any surface, any material, into an intelligent interactive zone. Our ultra-thin, flexible sensors can be easily integrated into an object, providing MultiTouch and pressure force feedback. Nanomade technology is so sensitive that it can also capture a user’s pulse.

1 MATERIAL + 1 SENSOR

= INFINITE INTERACTIONS

Nanomade expands the interactive experience

far beyond the touch screen.

Multi-material compatible, flexible, suitable for both small and large surfaces, our tactile and force solutions can be integrated anywhere, for any purpose.

FORM

0.3mm thickness for seamless integration into surfaces of all shapes: flat, curved, corrugated...

Material

ink that works everywhere: wood, metal, plastic, leather, glass...

Action

a technology that reacts to touch, impact, weight changes and the passive interactions of the human body.

GO TO MARKET

nanomade's capaforce© is a technology conceived and designed for easy integration into any process. We support innovation while maintaining the performance of your operations.

1 | DISCOVERY

Plug'n'play demo kits to test the technology.

2 | TEST

Production of a POC to validate the feasibility of the project.

3 | PROD

Production of sensors with the same exacting quality standards as the automotive industry.

OUR INSPIRATIONS

Imagination is the only limit

THEY SUPPORT US AND TRUST US

Since 2009, Nanomade has been developing innovative solutions for making any surface tactile. Nanomade's raison d'être is to imagine, develop and design the products that will tomorrow change the way we interact with objects.