Manufacturing

Curious about the technical intricacies of Nanomade’s cutting-edge deformation sensor technology?

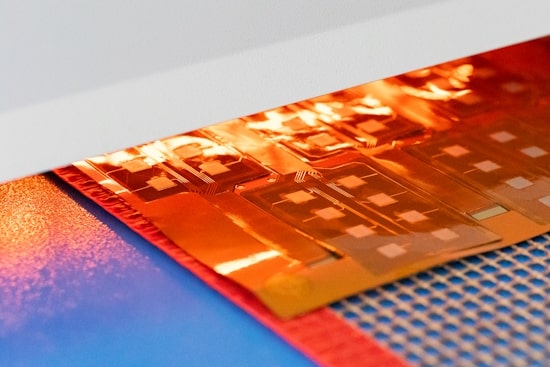

Our Manufacturing Capabilities

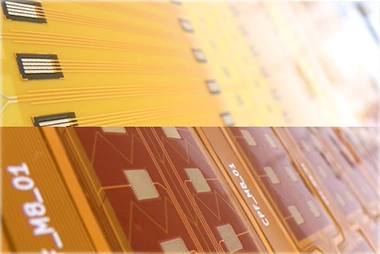

At Nanomade, we pride ourselves on our ability to produce high-performance deformation sensors at volume, ensuring that the most demanding industries, including automotive, aerospace, and consumer electronics, receive the highest quality solutions. Our advanced manufacturing processes are designed to meet the rigorous requirements for reliability, durability, and scalability, essential for missioncritical applications.

Nanomade Prototype Line

Our prototype line is a flexible and rapid-production facility capable of producing up to 10,000 sensors per year. This line is specifically designed for quick-turnaround projects and rapid prototyping to help customers validate designs and test concepts before moving into full-scale production. Whether for small-batch runs or customer-specific validation, our prototype line ensures the seamless transition from concept to production-ready sensors. The prototype line is also used for low-volume production runs, giving clients the flexibility to scale as needed.

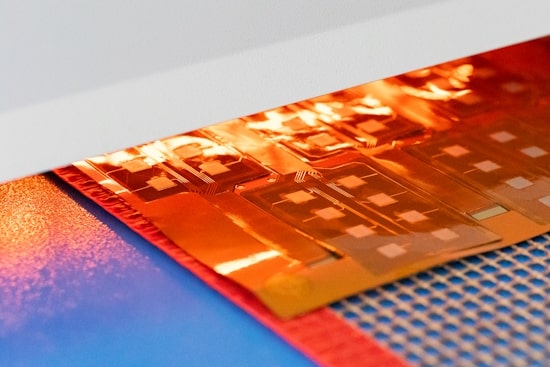

Nanomade Industrial Line

Launching in 2025, our industrial line will be capable of producing up to 1 million sensors annually, offering larger-scale production for industries where high-volume, high-performance sensors are required. This line integrates state-of-the-art automated assembly techniques that provide consistent quality and efficiency. With a focus on meeting the specific needs of industries like automotive and aerospace, this line ensures that Nanomade sensors are produced to the highest standards for performance, durability, and reliability, while maintaining competitive pricing.

Nanomade High-Volume Line with Industrial Partner

Currently operational, our high-volume line in partnership with an industrial leader enables the production of up to 10 million sensors per year. This line is equipped with all the necessary quality certifications, including ISO 9001, ISO 14001, and industry specific certifications required for aerospace, automotive, and consumer electronics.

Nanomade provides the proprietary ink technology that forms the core of our deformation sensors, while our industrial partner handles the integration and final assembly. This collaboration ensures scalability while maintaining the stringent quality and performance standards expected by our customers.

Nanomade’s manufacturing process ensures that all sensors meet high quality standards at every stage. We are fully equipped to handle global supply chain requirements while ensuring the best value and quality for our customers.

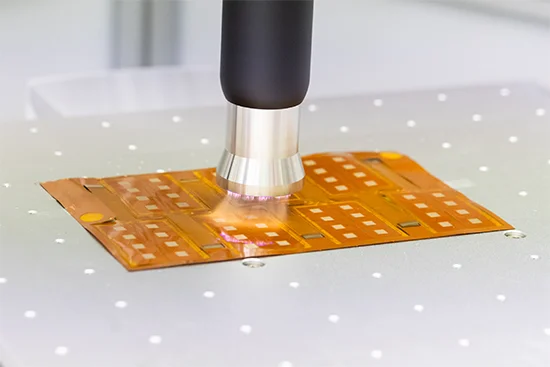

Quality and Certifications

As part of our commitment to excellence, Nanomade works closely with printed electronics industry leading partners who hold certifications required by the automotive and aerospace sectors and adhere to a strict quality management system. A detailed list of certifications can be found in the accompanying spreadsheets below.

General

| ID | Item | Reference |

|---|---|---|

| 1 | ISO | ISO9001-2015 |

| 2 | Terms and definitions for interconnecting and packaging electronic circuits | IPC-T-50 |

| 3 | General tolerances if not further specified, gerber and drawing is binding | DIN ISO 2768-m (Part 1 and 2) |

| 4 | Dimensions and tolerances | IPC-2615 |

Design

| ID | Item | Reference |

|---|---|---|

| 1 | Series of IPC pcb design specification documents | IPC-2220 Series |

| 2 | Design Standard for Printed Electronics on Flexible Substrates | IPC 2292 |

| 3 | Surface Insulation Resistance Handbook | IPC 9201 |

| 4 | How to avoid metallic growth problems on electronic hardware | IPC-TR-476 |

Material

| ID | Item | Reference |

|---|---|---|

| 1 | Flexible base dielectrics for use in flexible printed circuitry | IPC-4202 |

| 2 | Adhesive coated dielectric films for use as cover sheets for flexible printed circuitry and flexible adhesive bonding films | IPC-4203 |

| 3 | Flexible metal-clad dielectrics for use in fabrication of flexible printed circuitry | IPC-4204 |

| 4 | Qualification and performance of permanent solder mask | IPC-SM-840 |

| 5 | Guideline on flexibility and stretchability testing for printed electronics | IPC-9204 |

| 6 | Specification for electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards | IPC-4552 |

| 7 | Metal Foil for Printed board applications | IPC 4562 |

Manufacturing

| ID | Item | Reference |

|---|---|---|

| 1 | Series of IPC pcb performance specification documents | IPC-6010 Series |

| 2 | Pressure Sensitive Adhesive (PSA) assembly guidelines for flexible, rigid or rigid-flex printed boards | IPC-FC-234 |

Quality

| ID | Item | Reference |

|---|---|---|

| 1 | Acceptability of printed boards | IPC-A-600 |

| 2 | Test methods | IPC-TM-650 |

| 3 | Cross-cut test | EN ISO 2409 |

| 4 | Paints and varnishes – Pull-off test for adhesion | EN ISO 4624 |

The latest release is always valid.